Colour assessment to ISO 3668 with a viewing booth

Measuring instruments are only one part of comparing and quality controlling colours and substrates. Since no technical device is as precise as the human eye, the visual colour control is still essential for accurate quality control

The ISO 3668:2009 standard specifies how to assess coloured materials in manufacturing industries (automotive, plastics, textiles, furniture etc.). in contrast, visual colour machting in the graphic arts industry is described in the standard ISO 3664:2009.

| ISO 3664:2009 | ISO 3668, DIN 6173-2, DIN 5033 |

|---|---|

| Graphic technology and photography – Viewing conditions | Visual comparison of the colour of paints |

| Illuminant D50 (CIE) | Illuminant D65 (CIE) |

| Graphic arts industry | Manufacturing industries |

Viewing booths requirements

Reproducible conditions are necessary for standardised and repeatable colour matching processes. Natural dalight would be a good starting point for a light quality definition, but its light spectrum varies depending on time of day and location. Therefore, uniform viewing conditions require the use of colour matching areas using artificial daylight, CIE D65 being the most common in manufacturing industries.

The requirements for a viewing booth and its lighting defined in ISO 3668 are fulfilled by all JUST colour viewing cabinets:

- Either JUST LED moduLights or JUST fixtures equipped with JUST daylight 6500 proIndustry fluorescent tubes (illuminant D65) fulfill the required quality class BC

- Illuminance between 1000–4000 Lux (depending on model)

- Integral walls to shield extraneous light with matte, neutral gray colour surfaces (Munsell N7)

- Note: For very bright substrates, the inner walls should be brighter. For very dark substrates the inner walls should be matte black in order to reduce contrast between the environment and the coloured sample. Corresponding interior walls are available on request.

- Diffuse, uniform light without source reflections on the coloured substrates

- Operating hours meter to show when replacement lamps are required to continue meeting the standard

Standardised colour assessment

In order to standardise not only the viewing environment but also factor „human“, special requirement are placed on the observer. The observer must be perceive colour normally and should have experience in colour comparison as well as a good ability to distiguish different colours. Corresponding visual tests help to choose suitable observers. In addition, a neutral colour such as gray must be worn during the colour assessment.

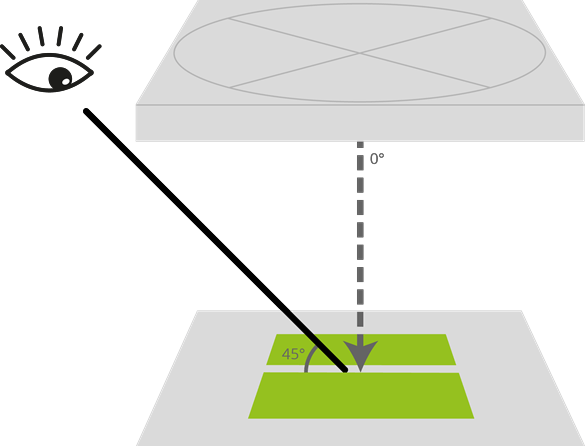

Two-dimensional sample plates need to be viewed with illumination of 0° by a viewing angle of 45° (measuring geometry 0°/45° and 45°/0° respectively). Howeder, certain application fields require different viewing and illumination angles, that is why appropriate sample holders are available in the web shop.

Colour differences are indicated to the ISO rating scale by hue, chroaticity and brightness. Finally, all details of the colour matching procedure should be recorded in an assessment report. A corresponding function to create such reports is available with the PROFESSIONAL series of the Color Viewing Light booths.

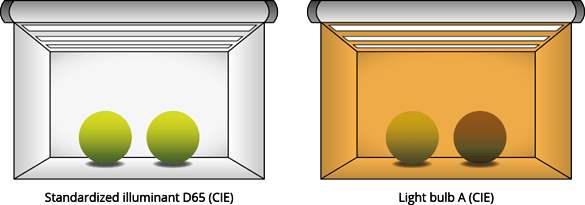

Detecting metamerism

Metamerism occurs when two colour samples appear equal under one viewing illuminant, but look different with another light. Note the substrates must also be assessed by CIE-illuminant A (incandescent lighting). In the illustrated example, both bodies have different spectrum, that may appear different depending on the illumination type and light source.

For standardised colour control it is necessary to choose D50 lighting for prints and D65 for industrial products, e.g. coatings, plastics, varnish etc. If detecting metamerism of the colours or substrates is required, additional illuminants/light sources are needed.

With JUST colour viewing booths you can choose between different dimensions and numbers of illuminants but they should always include at least illuminant D65 and A for detection of metamerism.

Recommendations for color assessment environments

- Comply with colour viewing / measuring geometry 0°/45° or vice versa. If necessary, use sample holders to provide the correct geometry.

- Put samples close together.

- If possible, colour samples should have the same dimensions

- Ambient conditions should be as neutral as possible. Try to avoid ambient light.

- For very dark substrates a light box with matte-black interior lining can be used to reduce the contrast. Otherwise the colour viewing booths must be neutral gray (Munsell N7).

- Obersers should wear neutral clothing to avoid reflections from their clothes.

- Only the viewing samples should be in the viewing booth at the time of assessment to avoid colour contamination from other samples

- The observer should be tested for normal colour vision and should have experience in visual color evaluations.

- Give your eyes time to adapt to the ambient conditions and do not look at any strong colours directly before the assessment

- If you own standards and guidlines are used, inform all parties who are involved in the colour assessment procedure and insepct conformance

- Use several different illuminants to detect metamerism

- If the substrates are fluorescent, UV radiation must be included in sources used for colour assessments

- Replace your fluorescent lamps regularly according to the manufacturer’s instructions. JUST Normlicht products contain an operating hours meter that shows to change lamps after 2,500 hours.

Source and further information:

DIN Deutsches Institut für Normung e.V. (2001): DIN EN ISO 3668:2001-12: Beschichtungsstoffe – Visueller Vergleich der Farbe von Beschichtungen (ISO 3668:1998); Deutsche Fassung EN ISO 3668:2001